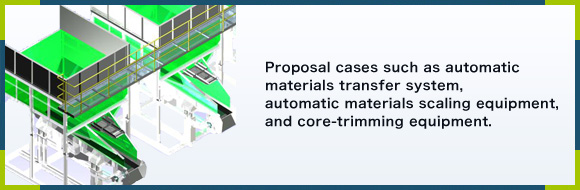

Saving of labor, stabilizing of quality, making speedy of production. For your needs of saving the cost, we will try with a lot of our experiences and know-how.

Casting plant melting materials automatic pouring equipment

Casting plant melting materials automatic pouring equipment Casting plant-automatic core-trimming equipment

Casting plant-automatic core-trimming equipment

Products outline

Series of conveying system included automatically measuring device. Full automatically measuring system is based on our excel technology.

Products outline

Ingot throw-in robot

Ingot throw-in robot

Materials can be taken out by robot technology by judging materials arrangement dealt by images processing.

Automatic materials collecting equipment

Automatic materials collecting equipment

Various materials can be scaled automatically using scale truck.

Materials of various patterns can be collected.

Precise scaling is possible for both ways of scaling truck and conveyor.

Problems before development

- The operational efficiency of the materials preparation-process in each time of melting should be increased.

(Throw-in times can be decreased by using robot.) - Scaling-precision should improved.(Man-made error can be made zero)

- Dealing with more complicated materials arrangement. (Automation by the order of up-stream computer.)

- The addition and expansion of the equipment by making use of the existing equipment.

- Durability improvement of the equipment.

- Automation for dangerous operation.

The point development

- Development of total pouring equipment using the robot technology and controlling system.

-

- Decreasing the materials pouring times and speed-up of the pouring process by continues pouring (maximum pouring quantity 4,000kg at one-batch)

- Multiple materials automatic scaling equipment coping with the difference of the figure and elements in materials. (Realization of total non-man power by remembering the pattern-arrangement at arrangement-setting equipment.)

- Usage of the parts equipped with the anti-shock and anti-cutting in throw-in truck by belt conveyor.

Product outline

Realization of the automation and quality improvement of the difficult core-trimming after casting.

- Automatic core-trimming equipment

- Various flash depending on products.

We are capable of making the full-automatic optimum proposal by considering the materials, figures, and process of the products.

Problems before development

- Scattering of fine particles, noise, and vibration in manual trimming, and operator’s fatigues.

- Capability to deal with carious flashes in different way of occurrence and size.

- Human-made error(quality-unevenness by operator)

The point to development

- Total automation of trimming operation by robot control.

-

- Decreasing the operator's burden without grinder operation.

(improvement of work-place surroundings) - Speed-up of operational efficiency (speeding-up)

- Total automation of series of operation from collecting fine particles to taking-out after washing.

- Uniformity of product quality.

- Decreasing the operator's burden without grinder operation.

-

- Above-shown product image is just one example.

There is no-limit to robot brand to use and specification in considering of version-up of the existing equipment. - We are capable of making proposal in considering of the layout capacity, product outline and man-potion of the customer’s production line by listening to customer’s detailed voices.

- Above-shown product image is just one example.